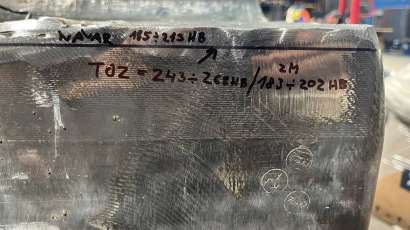

Weld overlay of missing material on a blade made of 42CrMo4 steel (0.42% C), with preheating using resistance pads and a Weldotherm unit. The filler material used was based on 1% chromium and 0.5% molybdenum. The hardness difference between the base material and the weld overlay was within 11 HB. The heat-affected zone had a hardness of 257 HB.

If the preheating had been incorrectly selected, there would have been a risk of hardening in the sub-weld zone up to 62 HRC.

In this case, everything turned out perfectly.